3West Environmental, Inc. Earns 2020 Best of Porch Award Award reflects company’s consistently high level of customer service San Clemente, CA, February 17, 2021 – 3West Environmental, Inc. is proud to announce that it has earned the home service industry’s coveted...

Blog

3West Enviro Business Hours

Monday – Friday

8:00 AM – 5:00 PM PST

Need to reach us?

Send us a detailed message using the form below.

After Hours?

We will respond to after hours requests the next business day.

Request Service

Please fill out the form below to request an estimate or schedule service.

Asbestos: Facts and Tips for Home Inspectors and Homeowners

What Is Asbestos? Asbestos is a mineral fiber that can be positively identified only with a special type of microscope. There are several types of asbestos fibers. In the past, asbestos was added to a variety of products to strengthen them and to provide heat...

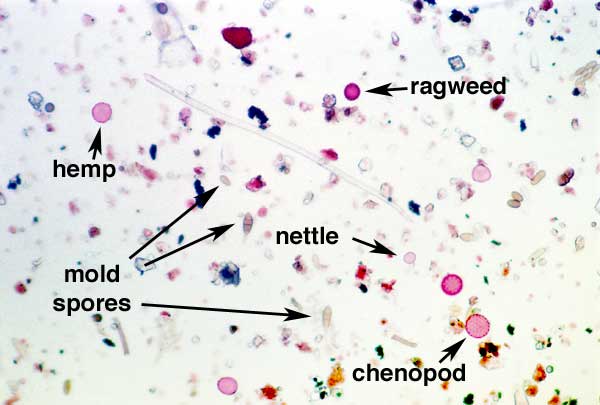

Air Sampling for Mold Inspections

Taking air samples during a mold inspection is important for several reasons. Mold spores are not visible to the naked eye, and the types of mold present can often be determinair sampleed through laboratory analysis of the air samples. Having samples analyzed can also help provide evidence of the scope and severity of a mold problem, as well as aid in assessing human exposure to mold spores. After remediation, new samples are typically taken to help ensure that all mold has been successfully removed.

Advantages of Solar Energy

Solar energy offers considerable advantages over conventional energy systems by nullifying flaws in those systems long considered to be unchangeable. Solar power for home energy production has its flaws, too, which are outlined in another article, but they’re dwarfed by the advantages listed below.

Abrasive Blasting for Mold Remediation

Abrasive blasting is a process for cleaning or finishing objects by using an air-blast or centrifugal wheel that throws abrasive particles against the surface of the work pieces. Sand, dry ice and corncobs are just some of the different types of media used in blasting. For the purposes of mold remediation, sodium bicarbonate (baking soda) and dry ice are the media commonly used.

10 Easy Ways to Save Money & Energy in Your Home

Most people don’t know how easy it is to make their homes run on less energy, and here at InterNACHI, we want to change that.

Drastic reductions in heating, cooling and electricity costs can be accomplished through very simple changes, most of which homeowners can do themselves. Of course, for homeowners who want to take advantage of the most up-to-date knowledge and systems in home energy efficiency, InterNACHI energy auditors can perform in-depth testing to find the best energy solutions for your particular home.

Building An Abatement Enclosure

https://youtu.be/wjGUrXOLvMY Building an Abatement Enclosure for Asbestos, Lead, Mold or Dust Control

Respirator Types

https://youtu.be/u_Dovk_khLw Types of Respirators This is a video about the different types of respirators that workers might use in their workplace. If your employer requires you to wear a respirator on the job, the federal Occupational Safety and Health...

Lead Paint Testing Requirements

Is lead paint testing a requirement in California? Yes. Any structure originally built before January 1, 1978 needs to be tested for lead-based paint. Here is some information on lead testing requirements in California. This information does not address local building...

Efflorescence

Efflorescence for Inspectors Efflorescence is the white chalky powder that you might find on the surface of a concrete or brick wall. It can be a cosmetic issue, or it can be an indication of moisture intrusion that could lead to major structural and indoor air...

Related Posts

3West Environmental, Inc. Earns 2020 Best of Porch Award

3West Environmental, Inc. Earns 2020 Best of Porch Award Award reflects company’s consistently high level of customer service San Clemente, CA, February 17, 2021 – 3West Environmental, Inc. is proud to announce that it has earned the home service industry’s coveted...

Air Sampling for Mold Inspections

Taking air samples during a mold inspection is important for several reasons. Mold spores are not visible to the naked eye, and the types of mold present can often be determinair sampleed through laboratory analysis of the air samples. Having samples analyzed can also help provide evidence of the scope and severity of a mold problem, as well as aid in assessing human exposure to mold spores. After remediation, new samples are typically taken to help ensure that all mold has been successfully removed.

Abrasive Blasting for Mold Remediation

Abrasive blasting is a process for cleaning or finishing objects by using an air-blast or centrifugal wheel that throws abrasive particles against the surface of the work pieces. Sand, dry ice and corncobs are just some of the different types of media used in blasting. For the purposes of mold remediation, sodium bicarbonate (baking soda) and dry ice are the media commonly used.