The Importance of Hazardous Materials Testing After Fire Damage When a fire damages a property, the focus often shifts to repairing structures and replacing belongings. However, fire-damaged properties can also harbor hazardous materials that threaten human health and...

Blog

3West Enviro Business Hours

Monday – Friday

8:00 AM – 5:00 PM PST

Need to reach us?

Send us a detailed message using the form below.

After Hours?

We will respond to after hours requests the next business day.

Request Service

Please fill out the form below to request an estimate or schedule service.

Asbestos Testing after Water Damage

Why You Need Asbestos Testing After Water Damage And How to Find the Right Company If your home has recently experienced water damage, you're likely overwhelmed with concerns about repairs, mold, and the safety of your living space. One thing that may not immediately...

Understanding Lead: Essential Facts

Understanding Lead: Essential Facts What You Should Know About Lead Exposure Lead exposure poses significant risks, especially to young children and babies before birth. Even seemingly healthy children can have elevated lead levels. Lead can enter the body through...

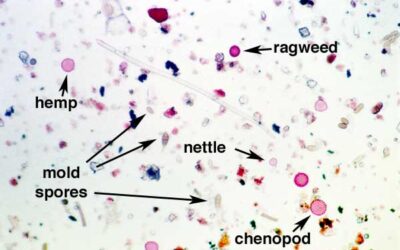

Air Sampling for Mold Inspections

Air Sampling for Mold Inspections by Nick Gromicko, CMI® and Ethan Ward During a mold inspection, taking air samples is crucial for several reasons. Mold spores aren't visible to the naked eye, and laboratory analysis of air samples can identify the types of mold...

Asbestos Cement Siding Inspection

Asbestos Cement Siding Inspection by Nick Gromicko, CMI® Asbestos cement is a composite material made from Portland cement reinforced with asbestos fibers. Manufacturers popularized asbestos cement siding before banning it in the U.S. in the 1970s. During inspections,...

SCAQMD Rule 1403 Procedure 5 Cleanup Plan

Understanding SCAQMD Rule 1403 Procedure 5 Cleanup Plan The South Coast Air Quality Management District (SCAQMD) has established Rule 1403 to regulate asbestos emissions from demolition and renovation activities. Among the procedures detailed in this rule is Procedure...

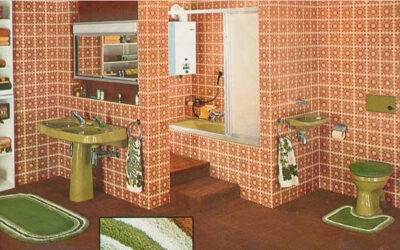

Carpeted Bathrooms

Carpeted Bathrooms by Nick Gromicko, CMI® and Kenton Shepard Carpeted bathrooms use carpeted floors instead of traditional surfaces like tile or vinyl. While carpets can enhance the bathroom's aesthetic appeal, they can also foster mold and bacteria. For this reason,...

Asbestos Regulations

What are the different regulations and laws regarding asbestos in California? In California, asbestos regulations and laws are primarily overseen by the California Department of Industrial Relations (DIR) and the California Division of Occupational Safety and Health...

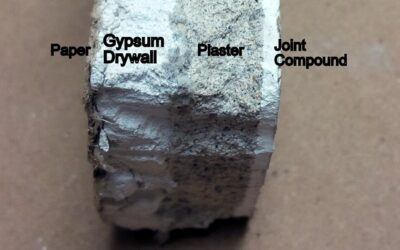

Asbestos Testing of Drywall or Plaster

If your walls or ceiling are going to be opened up for repair or remodeling, it is essential to have them tested beforehand. This is required by regulations to ensure the protection of the workers and residents involved, as well as for proper disposal purposes. Most...

5 Reasons to Do a Professional Mold Inspection After Water Damage

Homeowners dread water damage because of the terrible outcomes that occur if they cannot handle it appropriately. Water damage arises due to several reasons. It can be from an overflowing sink, damaged plumbing, broken window, flooding from natural disasters, or a...

Related Posts

Asbestos Cement Siding Inspection

Asbestos Cement Siding Inspection by Nick Gromicko, CMI® Asbestos cement is a composite material made from Portland cement reinforced with asbestos fibers. Manufacturers popularized asbestos cement siding before banning it in the U.S. in the 1970s. During inspections,...

SCAQMD Rule 1403 Procedure 5 Cleanup Plan

Understanding SCAQMD Rule 1403 Procedure 5 Cleanup Plan The South Coast Air Quality Management District (SCAQMD) has established Rule 1403 to regulate asbestos emissions from demolition and renovation activities. Among the procedures detailed in this rule is Procedure...

Asbestos Testing of Drywall or Plaster

If your walls or ceiling are going to be opened up for repair or remodeling, it is essential to have them tested beforehand. This is required by regulations to ensure the protection of the workers and residents involved, as well as for proper disposal purposes. Most...